C700 Oxygen Sensors

C700

Download data sheet

Nernst Calculator

Description

The C700 sensor is the first generation of SIRO2 oxygen sensor. It has been used and trusted for over forty (40) years, and is still in production today.

Specifications

| Thermal | ||||

|---|---|---|---|---|

| Parameter | Minimum | Typical | Maximum | Unit |

| Operating temperature † | 500 | 1200 | 1600 | °C |

| Ramp Rate | - | - | 600 | °C/hour |

| Storage | 5 | 20 | 50 | °C |

| Electrical | ||||

| Parameter | Minimum | Typical | Maximum | Unit |

| Output voltage range | 2.0 | 1130 | 1600†† | mV @ T ≥ 700°C |

| Output impedance | 1.00 | 2.00 | 10.00 | kΩ @ T ≥ 700°C |

| Response time | - | 2 | 10 | ms @ T ≥ 700°C |

| Offset Error @ 700° ⋆ ⋆ | - | ±2 | ±10 | mV @ pO2=pO2 |

| Measurement Range | ||||

| Parameter | Minimum | Typical | Maximum | Unit |

| O2 Atmosphere | 10-24 | - | 1 | pO2 @ 700°C |

| O2 Atmosphere | 10-12 | - | 1 | pO2 @ 1300°C |

| Reference Air | 10 | 40 | 100 | mL/min |

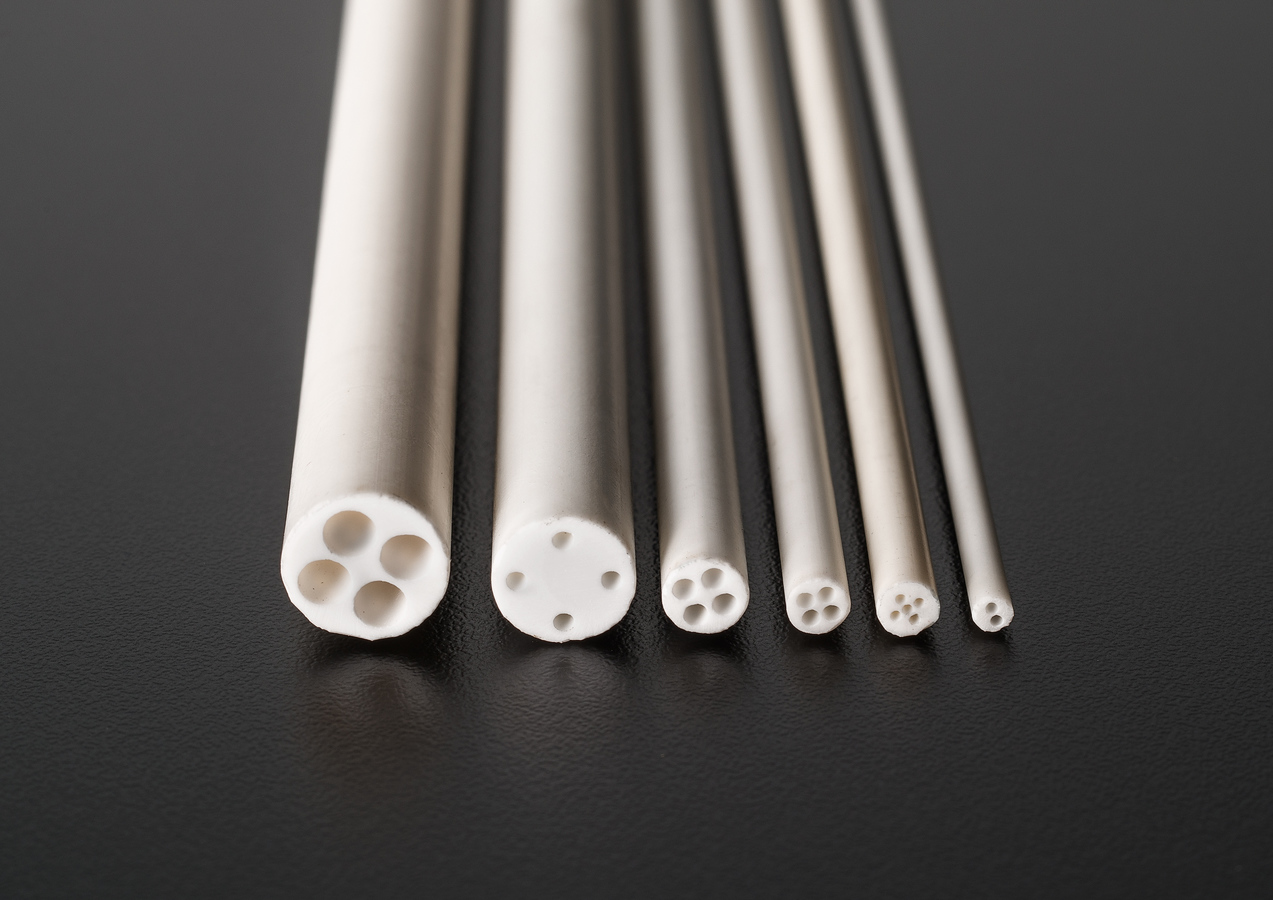

| Sensor Mechanical | ||||

| Parameter | Minimum | Typical | Maximum | Unit |

| Outer Diameter | 7.85 | 8.00 | 8.15 | mm |

| Inner Diameter | 4.90 | 5.05 | 5.20 | mm |

| Cut Length | 300 | - | 1400 | mm ± 3mm |

| Weight | - | 11.1 | - | g/100 mm |

† Continuous use of sensor above 1300°C reduces the lifetime of the sensor.

†† Under heavily reducing conditions, an output voltage of greater than 1650 mV may be observed. Readings about 1400 mV or greater than 1600 degrees may result in erroneous readings. Absolute maximum output voltage without damage to the sensor for the given atmosphere of 10-24 oxygen concentration. The sensor will provide an output response above 1130 mV, however lifetime cannot be guaranteed under these operating conditions.

⋆ Response times given here are applicable to most reducing atmospheres. Response times will vary depending on test gas type and may be slower for inert atmospheres.

⋆ ⋆ Offset error should be subtracted from the voltage reading during measurements for high accuracy applications. Also, note that this offset value if temperature dependent and that short hot zones/large thermal gradients across the sensor will contribute to higher offset errors.

The sensor within a probe can be installed anywhere in the kiln or furnace if used at temperatures below 1100°C. For operating temperatures above 1100°C, the probe should hang vertically, to avoid sag and loss of internal electrical contact.